Kev nce qib thiab cov yam ntxwv tseem ceeb ntawm FFX molding tshuab

(1) FFX txoj kev tshuab tuaj yeem tsim cov kav dej nrog cov qib steel siab dua, cov phab ntsa nyias thiab tuab dua. Txij li thaum deformation ntawm FFXerw yeeb nkab ua tshuabtxoj kev siv tshuab yog tsim los ntawm kab rov tav yob, thiab ntsug yob nyob rau hauv cov txheej txheem tom qab ntxhib tsis tas yuav siv cov yob sab hauv los tswj kev deformation, cov khoom siv muaj cov yam ntxwv ntawm ob qho tib si softness thiab rigidity, thiab nws yog ib qho yooj yim kom ua tau siab zog thiab siab rigidity thiab stabilize tsim cov khoom zoo welded 10 mm ~ 10 mm, saum toj no 2. qib mus txog P110.

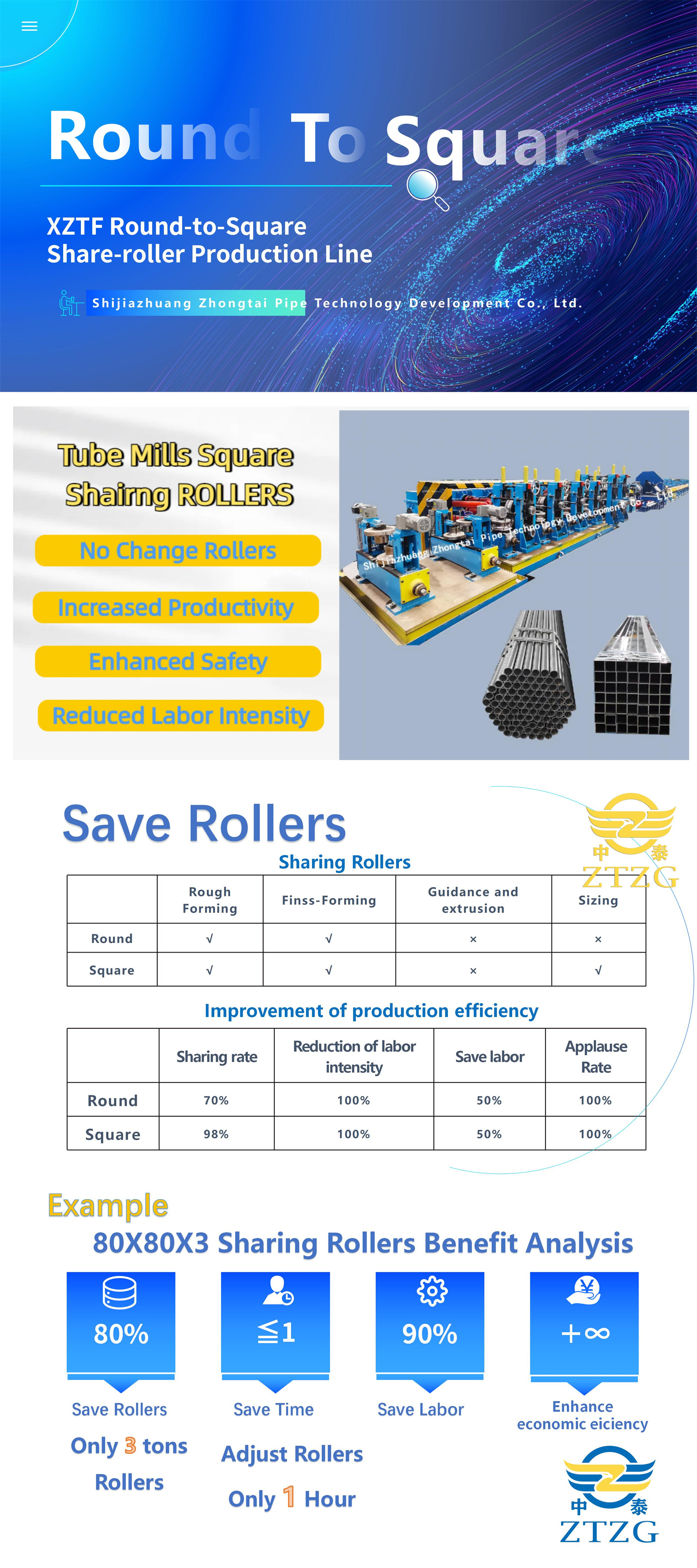

(2) Kab rov tav yob thiab ntsug yob ntawm FFX ua ntu hauv atube ua tshuabtau sib koom siab. Nyob rau hauv FFX txoj kev siv tshuab, involute yob puab thiab yob-rau-yob dabtsi yog khoov txoj kev yog organically ua ke, thiaj li hais tias kab rov tav yob thiab ntsug yob tuaj yeem sib koom ua ke. Piv txwv li, qhov thib peb-tiam ZTF yob cov yeeb nkab ua ntu hauv acev mill, tsim los ntawm ZTZG, tsuas yog yuav tsum tau muab cov txheej txheem yob rau kev sib sau ntxhib. Qhov no txo cov nqi ntawm cov yob thiab ua kom yooj yim rau kev siv thiab tswj cov yob.

(3) Kev faib tawm ntawm deformation yog tsim nyog, thiab cov txheej txheem molding yog ruaj khov. Nyob rau hauv lub rough forming theem ntawm acev mill, txoj kev loj deformation feem ntau yog siv cov kab rov tav chais, kom lub curvature ntawm sab ntawm lub qhib raj yog ze rau ntawm cov tiav welded yeeb nkab, thiab lub deformation ntawm zoo forming yog me me. Qhov no tsim nyog faib ntawm deformation ua rau txoj kev ruaj khov thiab kov yeej qhov tsis zoo ntawm kab yob txoj kev. Qhov kev phom sij zais cia ntawm welded yeeb nkab tsis xws luag yog tshwm sim los ntawm qhov tsis tsim nyog faib ntawm deformation hauv cov lauscev mills.

(4) Txoj kev nruam dabtsi yog khoov txoj kev, siv nyob rau hauv acev mill, yog saws los tsim qhov zoo tshaj plaws tej yam kev mob rau high-frequency vuam. FFX txoj kev siv tshuab, raws li siv nyob rau hauv atube ua tshuab, adopts txoj kev nruam dabtsi yog khoov txoj kev thiab ua rau tag nrho kev siv ntawm cov yam ntxwv ntawm cov kab rov tav yob thiab ntsug yob. Qhov no ua kom ntseeg tau tias tsis muaj qhov tuag ntawm qhov deformation nyob rau hauv seem sawb, thiab qhov tseem ceeb tshaj, nws ua tau zoo kov yeej cov deformation tshwm sim los ntawm kev hloov ntawm strip thickness thiab lub zog. Qhov txo qis ntawm elastic rov qab txhim kho molding raug thiab stability nyob rau hauv lubcev mill. Tom qab rough forming nyob rau hauv lubcev mill, lub ntug ntawm lub sawb hlau yog kiag li plastically deformed, thiab lub curvature ntawm ntug ntawm lub qhib raj yog ze heev rau ntawm lub tiav lawm raj. Lub deformation thaum lub sij hawm zoo sib sau yog tsawg, kom ntseeg tau tias cov duab ntawm lub qhib raj tom qab ntxhib forming yog khaws cia, uas tsim kom pom tej yam kev mob rau high-frequency vuam nyob rau hauv lubcev mill.

(5) Txhim kho qhov zoo ntawm cov yeeb nkab welded tsim los ntawm acev mill. Piv nrog rau cov txheej txheem yob txoj kev siv tshuab, FFX txoj kev siv tshuab, siv nyob rau hauv atube ua tshuab, kuj tseem txhim kho qhov zoo ntawm cov yeeb nkab welded nyob rau hauv ob yam nram qab no: Ua ntej, tom qab sib sau ntxhib nyob rau hauv lub cev mill, txij li qhov curvature ntawm ntug ntawm lub raj qhib yog ze heev rau lub cev yeeb nkab tiav, misalignment los ntawm extrusion rollers thaum lub sij hawm ua tiav yog txo qis, txawm tias muaj zog thiab tuab-walled welded kav. Tom qab fine forming nyob rau hauv lubcev mill, ob sab ntawm lub strip ntug yog qhov tseem ceeb thaum uas tig mus (tsis yog qhov zoo V-puab lossis inverted V-shape) pob qij txha. Uniform burrs yog tsim rau sab hauv thiab sab nrauv ntawm cov yeeb nkab welded, uas yog qhov zoo rau burr scraping. Nyob rau tib lub sijhawm, qhov loj dua V-zoo li lub vuam lub kaum sab xis tuaj yeem siv rau pem hauv ntej ntawm lub tshuab vuam tshuab, tiv thaiv vuam tsis xws li cov pob grey. Thib ob, vim txoj kev nruam flange txoj kev ua haujlwm nyob rau hauv lubcev millthiab qhov tshwj xeeb yob dhau tsim, ib feem ntawm cov sawb hlau tsuas yog dhau qhov siab tshaj plaws ntawm ib qho deformation thaum lub sij hawm sib sau ntxhib. Txoj kev hloov pauv ntawm deformation yog qhov zoo sib txuas, tiv thaiv ib qho ntawm ib cheeb tsam los ntawm kev rov qab deformed, thiab yog li, txo qis hauv zos thinning vim yob siab. Yog li ntawd, lub deformation yog uniform, lub internal kev nyuaj siab yog tsawg, thiab tag nrho cov sab hauv zoo ntawm cov welded yeeb nkab tsim los ntawm lubcev millyog txhim kho.

Txhawm rau ua kom tiav, peb ZTF-IV ERW yeeb nkab tsim tshuab, siv nyob rau hauv ibcev mill, sib txuas ntau yam zoo ntawm cov tsoos yob txoj kev thiab paj yob txoj kev, ua kom pom kev nce qib tseem ceeb. ZTZG tau tsim ntau ZTF welded yeeb nkab ntau lawm kab rau ntau lub lag luam. Ntawm lawv, Tangshan Wenfeng Qiyuan Steel tsim thiab tsim lub thib plaub tiam FFX tsis siv neeg tsim cov kab ntau lawm hauv lawv.cev mill, uas suav nrog kev tswj hwm lub computer, qhia tias ZTZG lub tswv yim tshiab tau nkag mus rau theem tshiab. Peb ZTF (FFX) Flexible Forming technology, siv hauvtube ua tshuab, yuav txuas ntxiv txhim kho thiab evolve los ntawm kev siv tsis tu ncua nyob rau hauv lubcev millib puag ncig.

Post lub sij hawm: Feb-04-2023